|

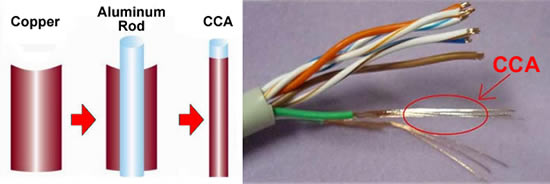

CCA (Copper Clad Aluminum)

CCA wire uses an aluminum conductor that is coated with copper and it is less expensive than pure copper. The use of CCA wire in twisted pair network cable is not permitted by the IEC or CENELEC in their cable standards, and 3P; an organization that provides third party testing for compliance with industry standards for cable manufacturers strongly advises against the use of CCA wire in twisted pair network cable. The use of CCA wire directly contravenes both CAT5e and CAT6 specifications which denote the use of copper conductors. CCA has higher attenuation properties than pure copper cable, this will result in more packets of data having to be retransmitted when it is corrupted or lost at the physical layer. This effect is particularly prevalent on longer cable channels on or near the 100meter maximum and will at best lead to a slower network for most users of CCA twisted pair cable. In addition to less desirable electrical qualities CCA wire presents a number of physical problems for installers ultimately leading to delay and additional expense. CCA wire has a lower tensile strength than pure copper and as such the cable can be damaged through pulling, with conductors or the whole cable breaking. CCA wire in twisted pair applications also has less tolerance for bend radius. BestLink Netware patch cables are made of 100% pure copper wire. |